-

-

- 2. Configuring BlackBox

- 2.1 Jumper Settings

- 2.2 Stepper Driver Settings

- 3. Connecting BlackBox

- 3.2 Connect Motors

- 3.3 Connect Tool

- 3.4 Connect Limit Switches

- 3.5 Connect Probe

- 4. Drivers and Software

- 5. Advanced Configurations

- 6. Frequently Asked Questions

- 7. Firmware

-

Sidebar

Table of Contents

3.7 Coolant Output

The Coolant output is primarily used to control chip-evacuation, dust-extraction or cutting fluid systems, but can also be creatively repurposed for other switching requirements.

It can be controlled with M-Codes:

- M8 = On

- M9 = Off

3.7.1 Electrical Specifications

- Max Current: 3A

- Voltage: 24v (Same as Input voltage)

- Suitable for inductive loads

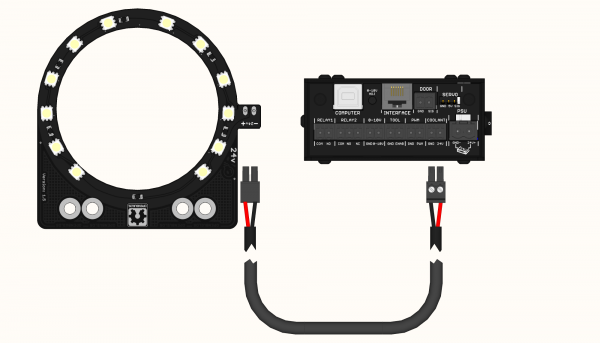

3.7.2 Connect OpenBuilds LED Ring

You can use the Coolant output to switch any other 24v device as well, as an example, you can connect your OpenBuilds Spindle LED Ring as shown to put it under M-Code control (for example if you want a Job to turn the LED ring on at the start and off at the end, you can add an M8 to the header and an M9 to the footer of your g-code)

3.7.3 Connect Dust Extraction via IoT Relay

You can use our IoT Relay Power Strip to control a Vacuum for dust extraction. Also checkout our Dust Shoe

Note: Even if you already have an IoT for your spindle, we recommend a second one for the Vacuum, as they are high current draw appliances and can overload the IoT relay if used with a spindle, and having a separate control signal for the Vacuum is a big bonus too.

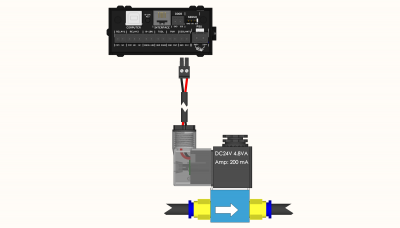

3.7.4 Connect 24VDC Air Solenoid

Page Tools

All rights reserved. This Documentation or any portion thereof including but not limited to (menu structures, images, layout, videos, graphical artwork, logos, names, trademarks, etc.) may not be reproduced or used in any manner whatsoever without the express written permission of OpenBuilds, LLC