Sidebar

Table of Contents

Troubleshooting CAD files

Not every DXF/SVG file you can find will be “CNC ready”.

Sometimes, you'll need to open a file in your CAD application (or even via multiple applications) and clean it up to make it work with CAM applications.

The following generic tips usually apply:

Closed Geometry Vectors

CAM software needs to calculate offsets to do contour cuts and pockets - and most of the mathematics require the vectors you want to use to be “closed vectors”

Closed vectors are shapes where the start-and-end points are the same. An open vector is a line/polyline that ends somewhere other than where it started.

Depending on the drawing and its purpose you can

- Use it only as an Engraving line (limiting the allowed operations to tools/toolpaths that follow the line)

- Manually edit and close the line (the example above is not suited to this, but sometimes you do have a shape meant to be closed but due to a drawing error, or file error, rounding mistake, etc the ends are just not closed when they should be)

- The file may not have been designed for CNC use, either redraw or use a different drawing.

Path Data / Polylines

Most CAM applications prefer their data to be “paths” (Not just OpenBuilds CAM, many others also work better with files that contain path/polyline type, simpler to process and import)

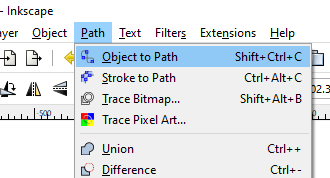

Paths (SVG)

In the case of SVGs, most vector editing applications has “to path” commands/menu items. This will convert all other entity types (splines, rects, circles, arcs, text, etc) to “paths”. Path data allows the machine to “follow” the line and better calculate offsets.

(Refer to the documentation for your CAD application to see whether they have a similar tool, as well as how to use it)

Polylines (DXF)

In the case of DXFs, the equivalent to SVG Paths, are DXF Polylines. Most DXF editing applications will have tools to convert other entity types to polylines, or to join seperate line segments into a Polylines. Polylines greatly enhance compatibility with most CAM applications

DXF Repair with QCAD

Checkout https://builds.openbuilds.com/threads/problems-with-importing-dxf-into-obcam.17132/#post-109203 for an example of using QCAD to repair a DXF where the entities are not all Polyline

File Versioning

Especially in the case of DXFs, there are multiple versions of the DXF file standard that was released over the years. If you have trouble importing a DXF into your CAM application, a good first port of call, would be to “save-as” the file and select an older version of the DXF standard, for example, DXF R14 Polylines

Page Tools

All rights reserved. This Documentation or any portion thereof including but not limited to (menu structures, images, layout, videos, graphical artwork, logos, names, trademarks, etc.) may not be reproduced or used in any manner whatsoever without the express written permission of OpenBuilds, LLC